Usually, Ring Joint Gaskets Manufacturer uses die-cut metal plates or flat rubber to make gaskets. The practice of die-cutting enables manufacturers to have strong design capabilities; the shapes of die-cut gaskets range from simple O-rings to complex automobile engine blocks. When the application requires thick and strong basic gaskets, manufacturers will choose to use rubber injection molding for die-cutting. Sometimes, the manufacturer also uses water jet cutting or compression molding to manufacture gaskets.

material

Non-Asbestos Gaskets Factory will select gasket materials according to its operating environment. Manufacturers can use a variety of synthetic materials, but the material they use the most is a synthetic rubber. The term "synthetic rubber" refers to a group of rubber materials, including neoprene, silicone, fluoroelastomer, EPDM, and various other standard and custom rubbers. Each of the aforementioned gasket materials has different degrees of non-reactivity, chemical compatibility, tensile strength, corrosion resistance, and extreme temperature performance. This material allowed a greater degree of control over harsh and irregular configurations, which revolutionized the industry.

For example, special synthetic rubber gaskets, such as sheathed polyester film gaskets and Teflon gaskets, can provide a reliable seal under the most dangerous chemicals or the harshest weather conditions.

For applications that require flexible sealing, manufacturers use sponge rubber to make foam gaskets, such as open-cell or closed-cell silicone rubber. Other material options include many non-asbestos boards such as filaments, glass fibers, ceramics, and Kevlar fibers.

Notes and customization

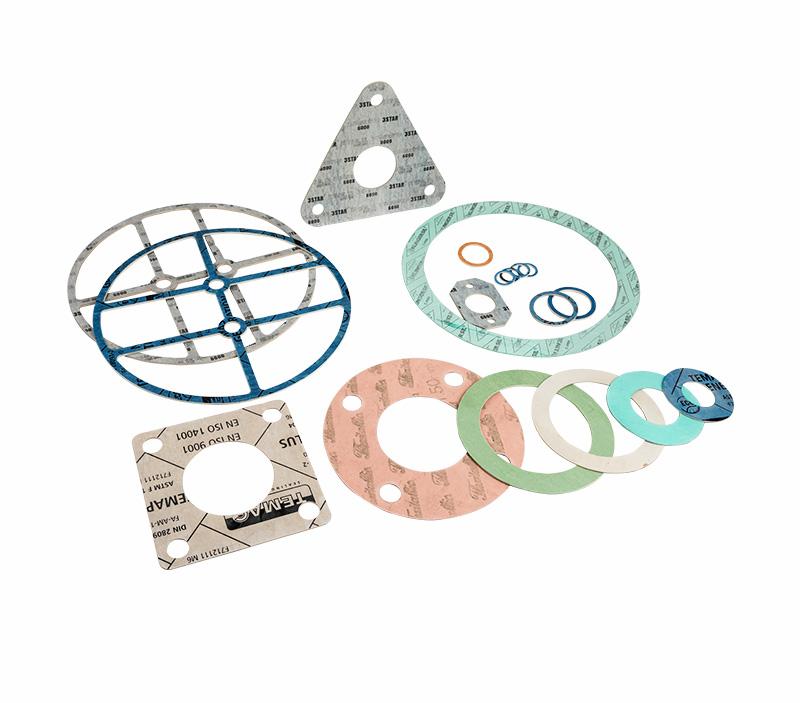

Gaskets have various compositions, shapes, and sizes. The manufacturer decides how to make your product based on your application requirements. If you wish, the manufacturer can customize the texture of the gasket to make it particularly suitable for connection points. Textures include tapering, grooving, wrinkling, and special shapes. They can also create custom gaskets using custom materials and dimensions.

species

Cylinder head gasket

To seal the gap between the engine block and cylinder head, the only option is the cylinder head gasket. Among the most complex gaskets, the head gasket is heat-resistant and chemical-resistant, and strong.

Gasket

In addition, in order to fill the gap or improve the sealing effect, the gasket can be used alone or in combination with a rubber gasket. The gasket is a flat metal gasket similar to a gasket.

O-ring

The O-ring gasket is named O after its shape. These thin gaskets are the most common of all gaskets used. They are popular because they are low cost, simple, easy to construct, and versatile. They can be used in static and dynamic mechanisms, such as hydraulic cylinders and rotating pump shafts.

Flange gasket

Like O-rings, flange gaskets are also named after their shape. Flange gaskets have protruding lips or edges that look like flanges. A flange is an inner or outer lip, rim, or ridge. The gasket lip helps the flange gasket to connect better.

Cylinder head gasket

Cylinder head gaskets, also called cylinder head gaskets, are components of internal combustion engines. There, they are wedged between the cylinder head and the engine block. Their goal is to provide effective sealing and compression while preventing fluid leakages such as oil or coolant.

Jacketed gasket

A Jacketed gasket is a gasket with an external metal coating on one or both sides (single jacket and double jacket respectively). Jacketed gaskets usually have a plastic or rubber interior, which is stronger, more durable, and more flexible than non-jacketed gaskets. Double-jacketed gaskets also have improved pressure resistance, high-temperature resistance, and corrosion resistance.

Intake manifold gasket

Intake manifold gaskets are another type of vehicle engine gaskets. They serve as the connection between the intake manifold and the top of the engine.

row

Air-cushion exhaust cushion is a special seal specially used to help regulate vehicle exhaust. They ensure that all gases leaving the engine remain in the exhaust system until the appropriate time.

Valve cover gasket

The valve cover gasket is a washer placed above the cylinder head of the engine, and its function is to prevent oil from leaking from the valve chamber.

Spiral wound gasket

Spiral wound gaskets are characterized by the combination or interweaving of metal and filler material into a spiral shape that is round outwards. The metal is usually stainless steel, and the filler is usually flexible graphite. In order to relieve pressure, tension or movement problems, manufacturers choose spiral wound gaskets. These gaskets provide a tight but flexible seal.

Silicone gasket

The manufacturer recommends using silicone rubber gaskets at extreme temperatures from -140°F to 480°F. They are also ideal in the face of ultraviolet rays because ultraviolet rays can both resist and shield other materials.

EPDM gasket

EPDM gaskets are used to match the surface of machine parts.

Neoprene gasket

Neoprene gaskets can be used with custom neoprene rubber and are known for their durability. They are used as permanent seals in the gaps between machine parts.