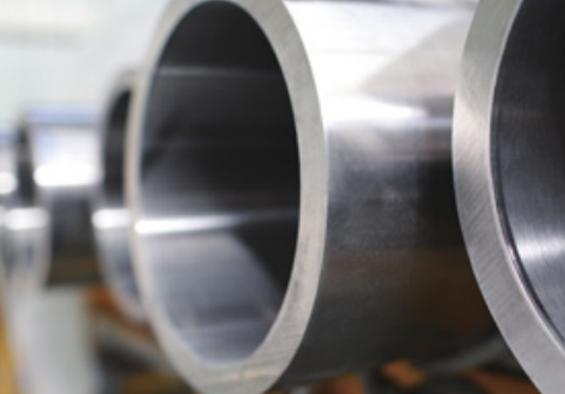

A cold drawing is to draw a metal pipe with a cold drawing machine without heating. The advantage is that it does not need to be carried out at high temperatures. The disadvantage is that the residual stress is large and the drawing cannot be too long. Cold drawing can improve the toughness and tensile strength to obtain better mechanical properties.

The process of cold drawn seamless steel pipe is mainly round tube billet → heating → perforation → heading → annealing → pickling → multi-pass cold drawing → semi-finished pipe → heat treatment → straightening → hydraulic test → marking → storage.

Cold drawing and cold drawing are two different methods of metal cold working, and the two are not the same concept. Cold drawing refers to the method of applying tensile force on both ends of a metal material to cause the material to stretch and deform.

Cold drawing refers to the method of applying a pulling force on one end of the material to pull the material through a mold hole. The diameter of the mold is smaller than the diameter of the material. The cold drawing process causes the material to have extrusion deformation in addition to the stretching deformation. The cold drawing process is generally carried out on a special cold drawing machine. The material processed by cold drawing has better performance than the material processed by cold drawing.

Huzhou Nanxun Yintuo Special Material Technology Co., Ltd. is committed to producing austenitic stainless steel seamless tube, super austenitic stainless steel seamless pipe and tube and other types of seamless tubes. If you need to purchase related tubes, please contact us.