Do you know that with a charcoal making machine you can recycle sawdust and transform it right into a merchandise that has higher economic value(mayor valor económico planta)? A simple sawdust biochar machine allows you to convert the biomass waste into sawdust biochar in only 20 mins. What's more, the conversion happens inside a sealed unit, which makes it safe, efficient and eco-friendly.

If you would like learn how to make biochar from sawdust efficiently, for instance, Beston can supply you with your own business plan and machinery price estimate. Further down the road, the organization also provide you with fast equipment installation services and operator training.

Past Sawdust Charcoal Machine Projects

Beston (cliente de BESTONECO)has customers from all of the across the globe. They may have successfully shipped and assembled sawdust charcoal machines in Spain, Ukraine, Russia and more. Look for about successful cases about the manufacturer's official website. Many of the cases have photographs and videos showing Beston's biochar machines 100 % operational mode. One of the many reasons why the company will be the go-to choice for biomass waste to charcoal equipment for a lot of is simply because their machinery employs advanced carbonization technology, unique structural engineering, modern carbonizing furnaces, high-grade components, effective emission cleaning technologies and more. The manufacturer's excellent after-sale services also helped to ensure they a famous global brand.

Sawdust To Charcoal Making Process

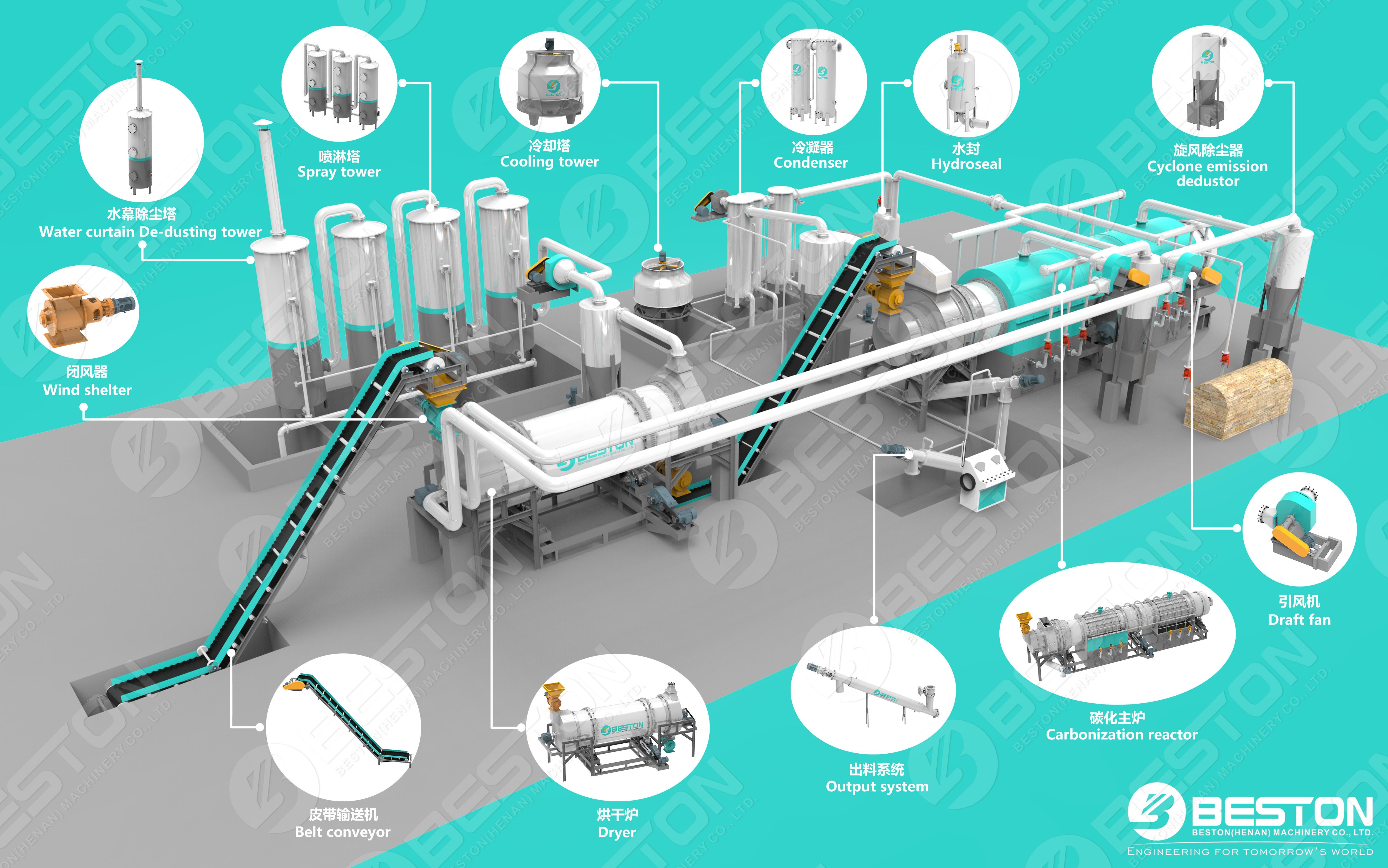

The whole process of converting sawdust into charcoal involves four key stages: drying, carbonization, emission cleaning and discharging. The drying stage might be skipped when the raw materials curently have a moisture content below 20%. Once the drying stage, sawdust is transferred into the carbonization furnace by way of a belt conveyor system. Because the temperature from the oxygen-sealed reactor begins to rise, combustible gas and biochar are designed.

Beston's sawdust charcoal machines are fitted with residual gas emissions units, that incorporate dedusting systems to reduce all sulfur from your combustible gas. The combustible gas is additionally sent via a condensing system (sistema de hacer carbon vegetal)to extract wood vinegar and wood tar. After passing from the purification systems, the resulting biogas is brought to refuel the carbonizing furnace.

After carbonization, the sawdust charcoal in the reactor is just too hot being directly collected. So, it really is sent by way of a discharging system that has an integrated air conditioning to lower the temperature of the biochar for safe collection.

Sawdust Charcoal Machine End Products

The ultimate products from a sawdust charcoal machine are bio charcoal, wood vinegar, wood tar, and biogas. The principle uses of sawdust charcoal include cooking fuel, soil fertilizer, and chemical processing. For usage in the chemical industry and metal refinery industry, bio charcoal is changed into activated carbon. The positive aspect of sawdust charcoal is it has a very high carbon content. What this means is it possesses a high caloric value and produces little smoke during burning.

For people wondering about value of other byproducts from the sawdust to biochar process, you should recognize that wood vinegar is definitely a good pest repellent. Wood vinegar can also be non-toxic, so it can be used in mosquito repellent spray for youngsters.