The electrical appliance mould is to make the blank into a mold and tool with a specific shape and size under the action of external force. It is widely used in punching, die forging, cold heading, extrusion, powder metallurgy parts pressing, pressure casting, and the forming and processing of engineering plastics, rubber, ceramics and other products by compression molding or injection molding. In short, a mold is a tool used to make molded objects. This tool is composed of various parts, and different molds are composed of different parts. It mainly realizes the processing of the shape of the article by changing the physical state of the formed material. Known as the "Mother of Industry".

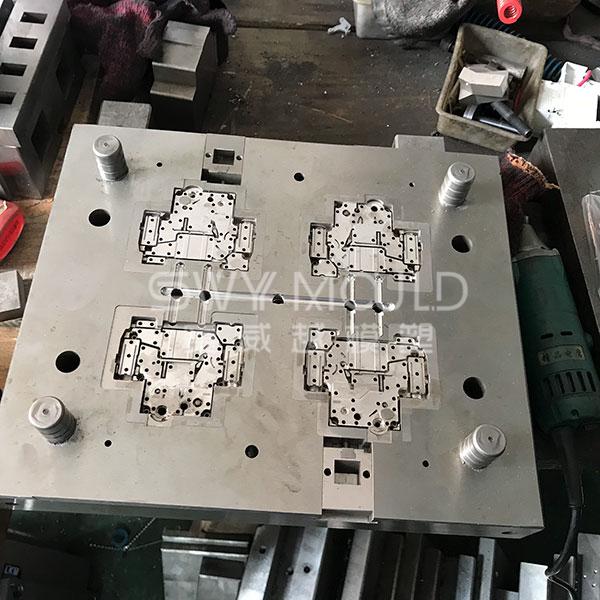

The mold has a specific contour or cavity shape, and the contour shape with a cutting edge can be used to separate the blank according to the contour shape (punching). The application of the cavity shape can make the blank obtain the corresponding three-dimensional shape. The mold generally includes two parts: a movable mold and a fixed mold (or a convex mold and a concave mold), which can be separated or combined. The mold is a precision tool with a complex shape and can withstand the expansion force of the blank. It has high requirements for structural strength, rigidity, surface hardness, surface roughness and processing accuracy. The development level of mold production is one of the important signs of the level of mechanical manufacturing.

The hot runner mold uses a heating device to prevent the plastic in the pouring system from solidifying or demolding with the product, so it is also called a runner less mold. Advantages: (1) No waste. (2) The injection pressure can be reduced, and multi-cavity molds can be used. (3) The molding cycle can be shortened. (4) Improving the quality of products is suitable for the characteristics of hot runner molding compounds, (5) The melting temperature range of plastics is wider. At low temperature, it has good fluidity and at high temperature, it has better thermal stability. (6) It is sensitive to pressure and does not flow without pressure, but it can flow when pressure is applied. (7) Good specific heat, so as to cool down quickly in the mold.

Regardless of whether it is an electrical mold or a TV set mould , the only plastics available for hot runners are PE, ABS, POM, PC, HIPS, PS. The commonly used hot runners include heated runner molds and insulated runner molds. The steel plate used in the mold part of the hard mold needs to be heat treated, such as quenching and carburizing, to meet the requirements of use. Such an injection mold is called a hard mold. For example, the inner mold part uses H13 steel, 420 steel, and S7 steel. The steel used in the inner mold of the soft mold (below 44HRC) can meet the requirements of use without heat treatment after being bought. Such injection molding is called a soft mold. For example, the inner mold uses P20 steel, 420 steel, NAK80, aluminum, and beryllium copper.