Introduction

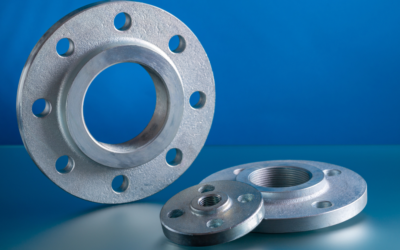

A flange is a projecting ridge or rim used to improve strength or weight distribution. Flanges join valves, pumps, pipes, and other pieces of equipment to form a pipeline system. It also enables easy washing, examination, and modification. Flanges are joined by welding or screwing. Flanged couplings are made by bolting two Flanges together and sealing the junction with a gasket.

Flanges are utilised when a piping junction needs to be removed. These can be found in a variety of places, including machines, valves, and specialised applications. Many Pipelines have Breakout Flanges placed at regular intervals where maintenance is required. Flanges, gaskets, and bolts are the three separate but interconnected components of a flanged joint. To produce a leak-proof joint, special controls must be applied in the selection and application of all of these components.

Materials used for Manufacturing Flanges

Pipe flanges are available in a wide range of materials and grades. Flanges can be made out of a variety of materials. Carbon Steel, High Yield Carbon Steel, Alloy Steel, Stainless Steel, Duplex and Super Duplex, and various Nickel Alloy Grades such as Monel, Inconel, Hastelloy, and Incoloy are the most often used materials for Pipe Flange production.

Different types of Flanges

Slip-on Flanges

Stainless Steel Slip-on Flanges are widely utilised due to their inexpensive material cost and ease of installation. You can also choose from a variety of various diameters and low-pressure variants. This Flange does not have a neck to rest on the pipe like Welding Neck Flanges, necessitating double welding.

Socket Weld Flange

Socket-weld flange is a Low-diameter, high-pressure pipes are commonly fitted with pipe flanges. Inserting the pipe into the socket end and adding a fillet weld around the top is how these Pipe Flanges are joined. This results in a smooth bore and better fluid or gas passage through the Pipe.

Threaded Flanges

Threaded Pipe Flanges are flanges that don't require welding to secure to a pipe. Internal threads on threaded flanges link to the pipe's external thread. Slip-on Pipe Flanges, which are utilised with Pipes having external threads, are identical to threaded Pipe Flanges.

Blind Flange

Because they are created without boring, blind flanges are used to blank off the ends of pipelines, valves, and pressure vessel openings. Blind flanges, particularly those in larger sizes, are the most heavily stressed Flange kinds in terms of internal pressure and bolt loading.

Lap Joint Flange

A lap-joint Flange is a two-part assembly that contains of a stub end with a lap-joint ring Flange positioned over it. After butt welding the stub end to the Pipe, the Flange ring can be rotated to align with the mating Flange. This Flange connection is generally useful for large or difficult-to-adjust Flanges.

Weld Neck Flanges

Welding Neck Flanges are distinguished by a long tapered hub that progressively extends across the pipe or fitting's wall thickness. Weld Neck Flanges are most commonly used to reduce the curve from a bigger to a smaller pipe size, resulting in higher pressure than before the run.

Reducing Flange

Without the use of a reducer, reducing flanges are utilised to link large and small pipe sizes. These flanges come in a variety of pressure classes and are suitable for joining two different pipe sizes. This type of Flange should not be utilised if a quick change, such as at a pump, might generate undesirable turbulence.

Read More :

Which Pipe Flanges Are Commonly Used In The Oil And Gas Industry? They come in a wide variety of shapes and sizes, including rounded, square, and rectangular sections. A Flange is typically used when connecting a pipe to a valve or another piece of equipment, To know more read further about Pipe Flanges

The Process of Fabricating Flanges Fabricating Flanges is a process that includes grinding and machining of the finished flange. Read more about fabrication of Flanges.

7 Benefits Of Using Steel Flange Fittings Steel Flange fittings are essential for any project and perfect to use in a variety of applications. Read more to know come benefits of Steel flange fittings

Flange Basics: Functions, Designs, and Other Considerations The flange on a valve is the two ends of a tube that are used to seal off the opening. The flange comes in many shapes and sizes, but all of them have a few important functions, Read to know basics.