Organic solid waste created by humankind happens to be a challenge due to its disposal. Filling it in landfills cuts into usable land, and also produces greenhouse gases from their slow decomposition that have led to serious environmental problems. Technologies are already developed to manage this waste, and one of these is pyrolysis(planta de reciclaje de neumaticos). It is a solution which includes been most effective in dealing with waste tyres, plastic, biomass, as well as other waste.

Organic matter is unstable at high temperature in oxygen free conditions. Pyrolysis uses this thermal instability t transform the organic matter int o products which can be used. It leads to a method of recycling that could be of big help to the environment. Organic waste is converted to gas that you can use for heating, an organic liquid that can be processed and refined further fr use, and solid residue. Temperatures in excess of 1000° C is possible by direct heating and final products are gases. Temperatures which is between 600°C and 700°C can produce oil from waste tyres and plastic. Temperatures below 600°C useful for treating biomass produces charcoal and combustible gas.

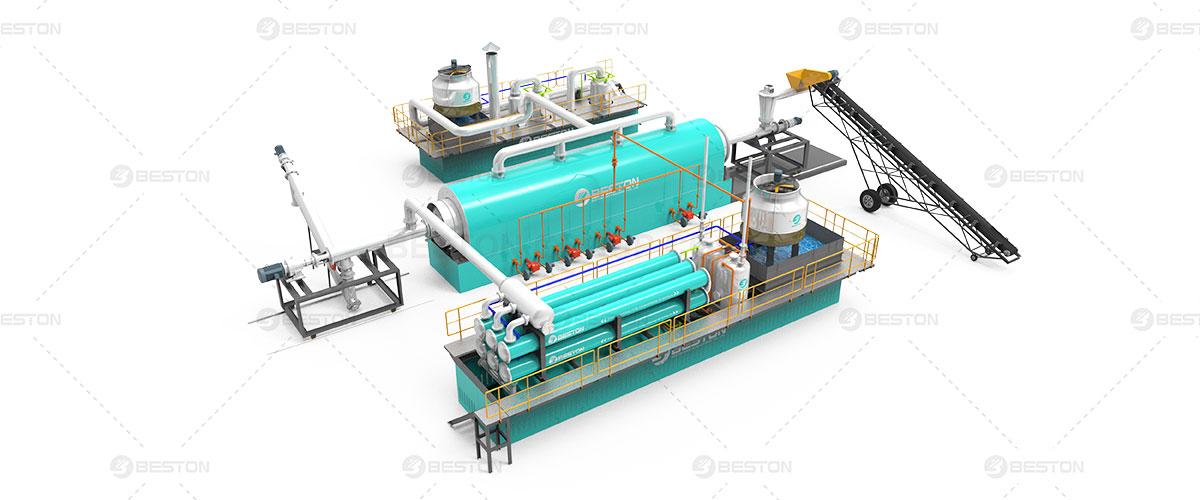

Pyrolysis plants(maquina para pirolisis de plasticos) are equipment designed to treat all types of organic waste , and convert them into useful products while ensuring the safe disposal from the waste. The key aspect of a pyrolysis plant is its reactor, wherein the waste material is burnt is at high temperatures in the absence of oxygen. Fuel used can be oil, gas, or wood. The gas produced during the process of pyrolysis is often processes and then fed back into the reactor for burning. This will reduce operational costs. The oil gas produced is at high temperatures and pyrolysis plants need to have a cooling system that cool the gas so it can be reused from the system. A condensing system retrieves heavy oil constitute the gas, which also needs to be filtered and removal of polluting elements. This oil can be used by a lot of industries. Carbon black is created through the residue left in fact the waste matter is pyrolyzed.

Pyrolysis plants(https://www.bestoneco.com/maquina-para-pirolisis-de-plasticos/) require some pre-processing equipment to ready the waste material before it is actually fed to the reactor. This can be grinding equipment to interrupt along the waste, shredding v and chipping equipment to lessen the dimensions of waste like old tyres and plastic, drying of wet organic municipal waste, and sieves or screens to eliminate solid metal, glass or timber that is generally a a part of waste. Conveyors or belts are necessary to convey the processed waste to reactors. Feeders are must feed reactors. Cooling and condensing equipment is needed to treat the gas, and retrieve oil.

Modern day pyrolysis plants are fully automatic(China Beston Group), right from the feeding of your waste in to the pre-processing equipment to retrieving the ultimate by products. A lot of them have instruments for control. Burners are designed into reactors, and arrangements may also be required for storing for any fuel essential for the burning. Continuous operation plants do not require