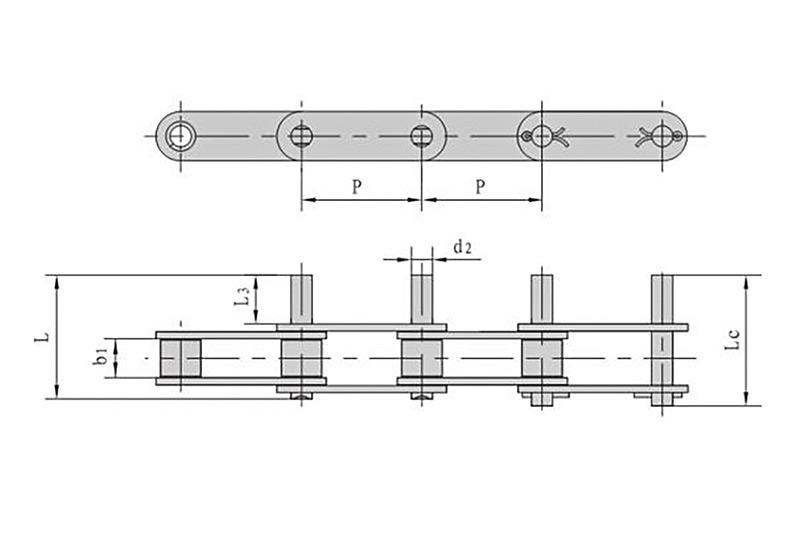

The manufacturers of Conveyor Chain share many well-known chains, which can be divided into transmission chains, delivery chains, decorative chains, tightening chains and special chains according to their use. According to the structure of the chain: it can be divided into roller chains, sleeve chains, plate chains, nylon roller chains, scraper chains, collar chains and so on. Most parts of the chain are composed of chain plate, chain pin, shaft sleeve and other components.

Other types of chains only make different changes to the chain plates according to different needs. Some are equipped with scrapers on the chain plates, some are equipped with guide bearings on the chain plates, and some are equipped with rollers on the chain plates. These are all for retrofitting stopped in different applications.

For ordinary chains, the smooth parts are mainly sprocket and chain roller, chain shaft and shaft sleeve. Due to the different structure of the chain, the smooth parts of the chain may also change. But in most chains, the smooth parts are mainly the rollers, chain shafts and bushings of the sprocket and chain.

Because the matching clearance between the shaft of the chain and the sleeve is small, smoothness is more difficult. Regarding special chains: such as chains equipped with bearings, rollers and other friction pairs, also consider the smooth parts of these friction pairs.

The main failure modes of the chain: A: pin break, B: pitch increase, C: sprocket tooth break, D: chain bite

Smooth oil should be selected as smooth as possible. For special chains and special conditions, smooth grease and dry film smoothing agent can be selected. Should meet the requirements of the chain when the chain is running to a large extent, and separate equipment and consumption requirements, choose a suitable, economical smoothing agent.

Conveyor Chain Manufacturers Introduce The Classification Of Chains