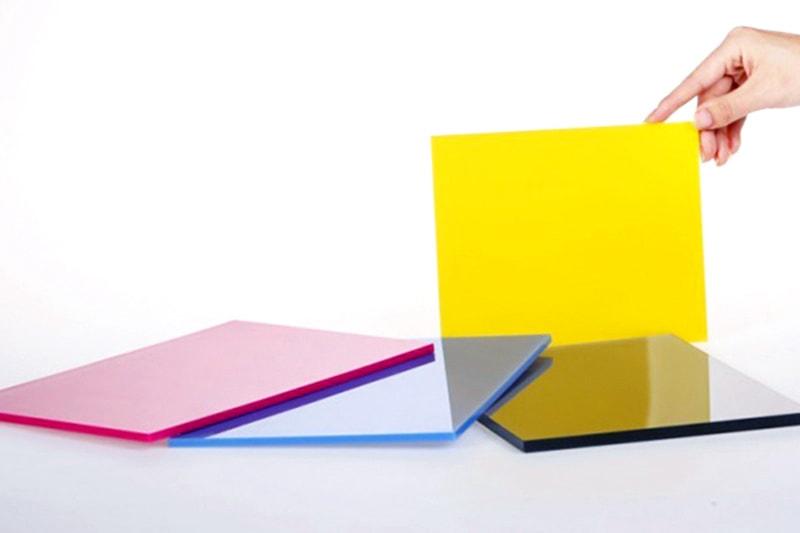

Acrylic , more commonly known as PMMA or plastiglass, is very popular these days. To meet ever-changing performance requirements, acrylic is produced in various colors (transparent sheets, paint sheets, and variants of dark).

According to the color transparency, acrylic board can be categorized as a)transparent colored acrylic sheets, 2)colored acrylic sheets, 3) dark acrylic sheet 4)tinted plexiglass sheets such as high impact glass, flame retardant, frosted plate, light-guiding, and metal-reinforcing plate, and so on

Acrylic is classified as extrusion and casting according to the method

air of heavy weight, high molecular density, superior plasticity, adequate elasticity and chemical resistance

A:extrusion has lower molecular weight, more pliability, poorer mechanical properties, and is more flexible.

Acrylic also has a kind of revolving drum, which are acrylic leftovers from previous projects that are reused as materials for future projects. The regenerated MMA monomer is reacted with dimethyl acrylamine, and the resulting oligomer is then polymerized. When the monomer is exposed to a harsh treatment, it can be re-synthesized and is indistinguishable from the original monomer. However, after plate-forming, the degradation purity of the degrades.

It's conclusion is that a granular raw materials which has been subjected to high-temperature dissolution is cast with high-monomer (HTC) (liquid). Although the extrusion plate appears smooth and fully polymerized, it achieves the synthesis of granulation in the process. It does not hold up well when processed into boards, and is therefore not appropriate for outdoor identification, so it is only suitable for items like crystals or other products that must withstand temperature fluctuations like resin characters.

The outdoor service of extruded metal does not contain UV inhibitors, making the color fade rapidly and cracking more likely because of exposure to sunlight. The kind of polymerization that takes place when casting plates are made is called structural, because of the significance of the way they're built, and it has a high absorption capacity for ultraviolet light. You should expect it to last even longer than that, because it's been outside for much longer than that, and it's still as fresh as the day it was when it was delivered.

For Acrylic plastic manufacturing, a screen print screen printing machine is usually used to obtain the color and patterns. The darkroom, a screen printing table, screen printing equipment, chemicals, screen printing inks, photosensitive plate, scrapers, emulsion, wash and neutral solution all have to be imported from Switzerland.

Contrast enhancement: 1. Check the contrast of the photosensitive glue In most cases, the photosensitive glue should be adjusted manually. The bottle is leaking a little. Stir it up and dump it in the resin. The time to expose the glue should be approached as if it were now, or start operating in the dark. One thing is certain: it will go bad the moment it sees the light of day (proverb). Capsulation protects against light and oxidation, and covers well after use, keeping things safe from exposure to light. Next, coat the photosensitive adhesive around the screen with a light layer. There should not be too much material in the gun doesn't go through easily, but not be lacking any either.

They dried themselves in the oven

When air is exhausted from the printing process, people can leave the darkroom; the ultraviolet radiation of the machine is not being generated yet. When the printing has finished, the screens will come out by themselves. If the area is fully unlighted, the pattern will show through. In cases where there are any air leaks, you need to cover the leaks with adhesive tape, or the printer can leak color from the tiny leaks. After making the tray, remove the spatula and use the dustpan.

Insert the projector into the printer at the front of the printing table and then slide it into the locked slot. Attach the acrylic board to the printing table, then place the patterned portion in the water and apply the slowly drying agent. Then slowly press on the board until the color runs out of the patterned areas, and scrape. The job is over.