Patrocinado

Taizhou Shuanghao Plastic Mould Co.,Ltd is famous China Plastic products Manufacturers and Plastic products factory. We specialized in designing and manufacturing plastic cap mold, PET preform mold, blowing mold with our own mould factory.AD/CAM/CAE system for designing and engineering mould products.We design and use standard moul frame and use pricision 3D printer and CNC tooling machine to make parts, in order to ensure the quality of the moulds. We also wholesale Plastic products, other molds and service.

- 8 Publicações

- 3 fotos

- 0 Vídeos

- Male

- 18/03/1990

- Seguido por 0 pessoas

Atualizações Recentes

- https://www.sunmolds.com/machine/plastic-related-package-machines/cap-folding-and-slitting-machione.htmlWWW.SUNMOLDS.COMChina Cap folding and slitting machine Suppliers, Factory - Taizhou Shuanghao Plastic Mould Co.,LtdTaizhou Shuanghao Plastic Mould Co.,Ltd is a China Cap folding and slitting machine suppliers and wholesaler,Machine main structure: Sorting bin(Vibrating disk or Centrifugal pan), Channel, Die hea...0 Comentários 0 Compartilhamentos 88 Visualizações 0 AnteriorFaça Login para curtir, compartilhar e comentar!

- https://www.sunmolds.com/product/cap-mould/plastic-cap-mould.html

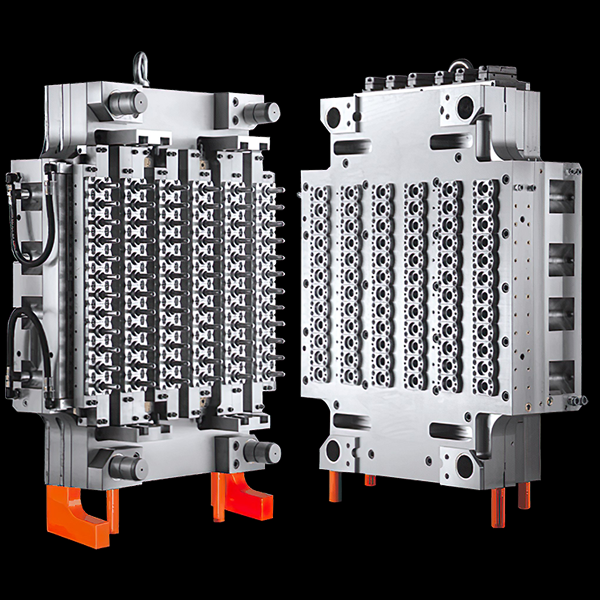

Product Name Plastic Cap Mould

Core &Cavity Steel 2316#steel, S136, H13, 718, SKD61, P20, S50C, 45#steel, 4Cr13,

3Cr13, BeCu or based on customer's requirement.

Mould base & Standard Component DME,HASCO,MISUMI,LKM,Self-made etc.

Steel hardness: HRC30-35 for base material.

HRC45-48 for core and cavity material.

HRC60-62 for special parts material

Plastic material PP,,PE,HDPE etc.

Cavity Number 1*4, 1*6, 1*8,1*12, 1*16, 1*24, 1*32, 1*48 etc

Injection System Pin gate, Submarine gate, Valve gate etc

Ejector System Unscrew by motor, stripper plate, ejector sleeve, ejector pin

Cycle Time Based on cap design

Tooling lead time 30-60 Days

Mould life At least 1.5million Shots

Quality assurance ISO9001:2008/ CE certificate for European customershttps://www.sunmolds.com/product/cap-mould/plastic-cap-mould.html Product Name Plastic Cap Mould Core &Cavity Steel 2316#steel, S136, H13, 718, SKD61, P20, S50C, 45#steel, 4Cr13, 3Cr13, BeCu or based on customer's requirement. Mould base & Standard Component DME,HASCO,MISUMI,LKM,Self-made etc. Steel hardness: HRC30-35 for base material. HRC45-48 for core and cavity material. HRC60-62 for special parts material Plastic material PP,,PE,HDPE etc. Cavity Number 1*4, 1*6, 1*8,1*12, 1*16, 1*24, 1*32, 1*48 etc Injection System Pin gate, Submarine gate, Valve gate etc Ejector System Unscrew by motor, stripper plate, ejector sleeve, ejector pin Cycle Time Based on cap design Tooling lead time 30-60 Days Mould life At least 1.5million Shots Quality assurance ISO9001:2008/ CE certificate for European customersWWW.SUNMOLDS.COMChina Plastic Cap Mould Suppliers, Factory - Taizhou Shuanghao Plastic Mould Co.,LtdTaizhou Shuanghao Plastic Mould Co.,Ltd is a China Plastic Cap Mould suppliers and wholesaler,Product NamePlastic Cap MouldCore &Cavity Steel2316#steel, S136, H13, 718, SKD61, P2...0 Comentários 0 Compartilhamentos 185 Visualizações 0 Anterior - https://www.sunmolds.com/plastic-products/pet-preform/30mm-pet-preform.htmlWWW.SUNMOLDS.COMChina 30mm PET Preform Suppliers, Factory - Taizhou Shuanghao Plastic Mould Co.,LtdTaizhou Shuanghao Plastic Mould Co.,Ltd is a China 30mm PET Preform suppliers and wholesaler,Product description1) 100% new material2) High transparency3) High toughness4) Different...0 Comentários 0 Compartilhamentos 90 Visualizações 0 Anterior

- 1 to 5 gallon PET preform mould

https://www.sunmolds.com/product/pet-preform-mould/1-to-5-gallon-pet-preform-mould.html

1 to 5 gallon PET preform mould https://www.sunmolds.com/product/pet-preform-mould/1-to-5-gallon-pet-preform-mould.htmlWWW.SUNMOLDS.COMChina 1 to 5 gallon PET preform mould Suppliers, Factory - Taizhou Shuanghao Plastic Mould Co.,LtdTaizhou Shuanghao Plastic Mould Co.,Ltd is a China 1 to 5 gallon PET preform mould suppliers and wholesaler,Product Name1 to 5 gallon PET preform mouldCore &Cavity Steel2316#steel, S136 stainl...0 Comentários 0 Compartilhamentos 136 Visualizações 0 Anterior - https://www.sunmolds.com/product/blow-molding-machine/semi-automatic-blow-molding-machine.html

Semi automatic blow molding machine

1.Stable performance with advanced PLC and conveying preforms automatically with conveyor.

2.Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheater.

3.High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area and eternal temperature in the preheater with an automatic thermostatic apparatus.

4.High safeties with security automatic-locking apparatus in each mechanical action,which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

5.No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

6.Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

7.Strong clamping force with high pressure and double crank links to lock the mold.

8.Two ways of operating: Automatic and manual.

9.Safe,reliable and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

10.Low cost,high efficiency,easy operation,easy maintenance,etc.

11.Contamination is avoided for the bottle body.

12.Ideal effect of the chilling with the chilling system for the bottle mould.

13.Easy installation and starting.

14.Low rejection rate:less than 0.2 percent.

15.Full automatic machine, one man is enough for operation the machine.

16.Adopt the new type double bend arm and the four rod-clamping structure(won the patent): Cross direction; Middle mould board is move parallel; the distance between two mold board is adjusted by the chain wheel. Thus, the clamping force is very strong.

17.Power saving design that can increase your profits.

18.Separated type air controlling system, which is designed for avoiding waste pollution.

19.The preheater of PP blow machine should be more bigger than PET blow machine.https://www.sunmolds.com/product/blow-molding-machine/semi-automatic-blow-molding-machine.html Semi automatic blow molding machine 1.Stable performance with advanced PLC and conveying preforms automatically with conveyor. 2.Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheater. 3.High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area and eternal temperature in the preheater with an automatic thermostatic apparatus. 4.High safeties with security automatic-locking apparatus in each mechanical action,which will make the procedures turn into a state of safety in case of a breakdown in certain procedure. 5.No contamination and low noise with the air cylinder to drive the action instead of the oil pump. 6.Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine. 7.Strong clamping force with high pressure and double crank links to lock the mold. 8.Two ways of operating: Automatic and manual. 9.Safe,reliable and unique design of the position of valve to make the air pressure diagram of the machine easier to understand. 10.Low cost,high efficiency,easy operation,easy maintenance,etc. 11.Contamination is avoided for the bottle body. 12.Ideal effect of the chilling with the chilling system for the bottle mould. 13.Easy installation and starting. 14.Low rejection rate:less than 0.2 percent. 15.Full automatic machine, one man is enough for operation the machine. 16.Adopt the new type double bend arm and the four rod-clamping structure(won the patent): Cross direction; Middle mould board is move parallel; the distance between two mold board is adjusted by the chain wheel. Thus, the clamping force is very strong. 17.Power saving design that can increase your profits. 18.Separated type air controlling system, which is designed for avoiding waste pollution. 19.The preheater of PP blow machine should be more bigger than PET blow machine.WWW.SUNMOLDS.COMSemi Automatic Blow Moulding Machine Manufacturers,SuppliersTaizhou Shuanghao Plastic Mould Co.,Ltd is a famous China semi automatic blow moulding machine suppliers and semi automatic blow moulding machine manufacturers0 Comentários 0 Compartilhamentos 99 Visualizações 0 Anterior1

- https://www.sunmolds.com/product/cap-mould/0 Comentários 0 Compartilhamentos 117 Visualizações 0 Anterior

- 0 Comentários 0 Compartilhamentos 86 Visualizações 0 Anterior

- 0 Comentários 0 Compartilhamentos 98 Visualizações 0 Anterior

Mais Stories