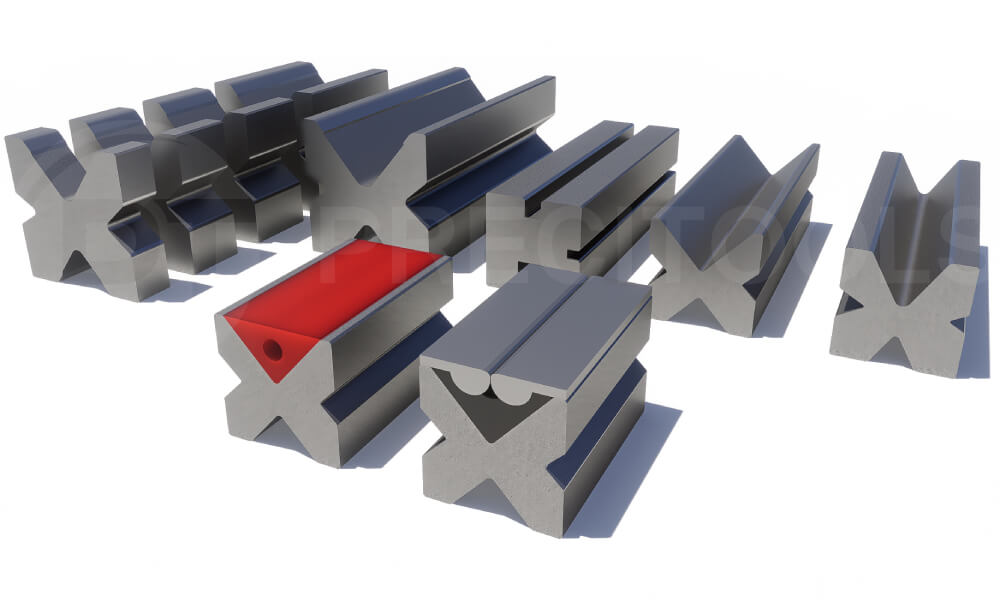

For the Promecam tooling system, we offer 4V and 3U bending dies. These dies are the most universal product for starter sets for press brakes and have the economic possibility of working with different thicknesses. These dies could just be turned around to get other V-openings. It is also very effective for the customer who just starts to work with the press brake and has the necessity to prepare their actual parameters for die opening and tonnage to be used.

We also have a polyurethane insert for the V50 opening, so you can work to bend in polyurethane as well. And together with our 3U die, you can have the complete range of main used openings from 6 mm.

In other systems, these dies could be used with adapters. Contact us if you need any additional information.

More information here:

https://blog.precitools-it.com/4v-bending-die-the-best-product-for-promecam-press-brakes/

#pressbraketools #bendingtooling #pressbrake #pressbraketooling #bendingtools

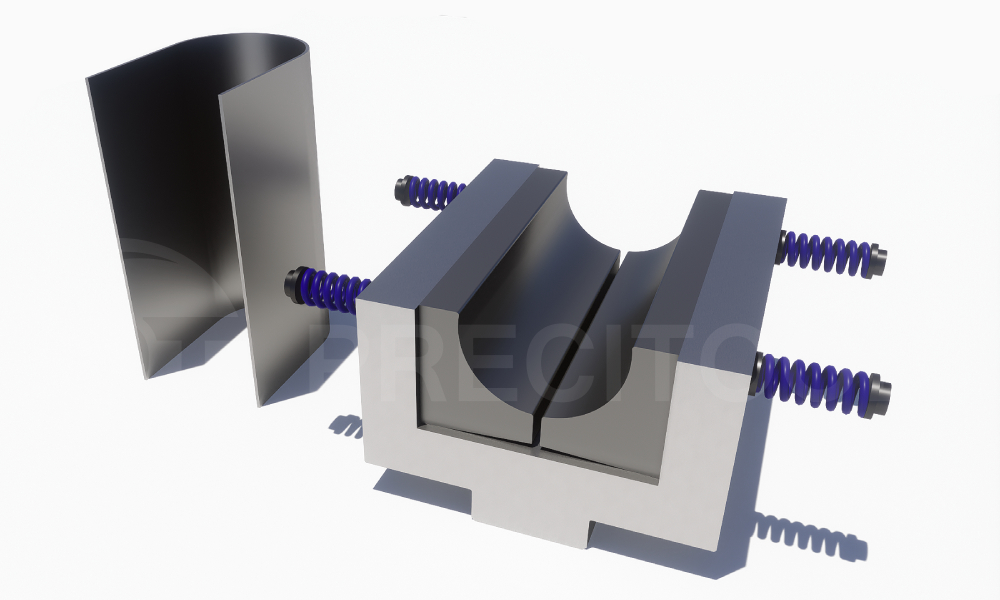

We also have a polyurethane insert for the V50 opening, so you can work to bend in polyurethane as well. And together with our 3U die, you can have the complete range of main used openings from 6 mm.

In other systems, these dies could be used with adapters. Contact us if you need any additional information.

More information here:

https://blog.precitools-it.com/4v-bending-die-the-best-product-for-promecam-press-brakes/

#pressbraketools #bendingtooling #pressbrake #pressbraketooling #bendingtools

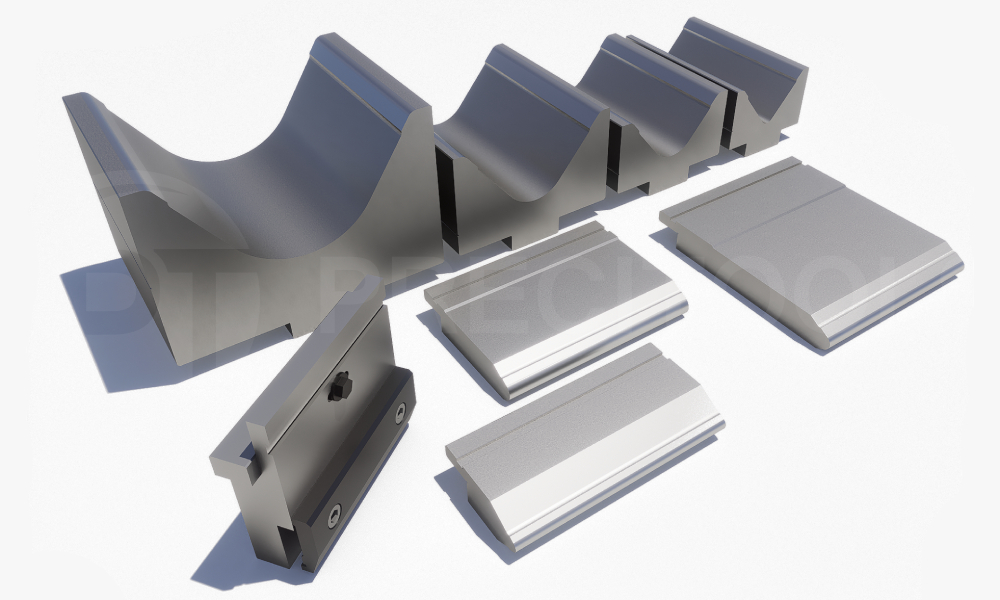

For the Promecam tooling system, we offer 4V and 3U bending dies. These dies are the most universal product for starter sets for press brakes and have the economic possibility of working with different thicknesses. These dies could just be turned around to get other V-openings. It is also very effective for the customer who just starts to work with the press brake and has the necessity to prepare their actual parameters for die opening and tonnage to be used.

We also have a polyurethane insert for the V50 opening, so you can work to bend in polyurethane as well. And together with our 3U die, you can have the complete range of main used openings from 6 mm.

In other systems, these dies could be used with adapters. Contact us if you need any additional information.

More information here:

https://blog.precitools-it.com/4v-bending-die-the-best-product-for-promecam-press-brakes/

#pressbraketools #bendingtooling #pressbrake #pressbraketooling #bendingtools

0 Comments

0 Shares

412 Views

0 Reviews